Screen printing enables high-saturation, high-octane color printing, accurately rendering vibrant brand logos, gradient colors, and patterns with varying textures such as matte and glossy.For glass perfume bottles made of different substrates—transparent, frosted, or colored—screen printing inks can be specifically formulated to ensure uniform color and prevent color bleeding,Screen printing can be combined with hot stamping, UV spot varnishing, perfectly matching the visual style of high-end perfume brands.

Glass bottle hot stamping custom logo With a smooth, non-sticky finish, it exudes a more refined and luxurious feel compared to screen printing and labeling. It is abrasion-resistant, scratch-resistant, and solvent-resistant, maintaining its clarity and integrity for a long time. The hot-press printing process allows for precise customization of fine lines, tiny text, and complex logos, It also supports a variety of colors (gold, silver, red, black, etc.) and effects (matte, glossy, laser), allowing for flexible design based on brand image and meeting the personalized customization needs of different perfume bottles.

3D printing is a special process ,3D-printed logos have a three-dimensional embossed/sculpted effect, offering a distinct tactile texture. Visually, they are more recognizable and sophisticated than flat screen printing or hot stamping, enhancing brand visual memorability. For example, high-end perfume brands often use 3D logos to highlight their luxury positioning, a need perfectly met by 3D printing.3D printing eliminates the need for harsh chemicals, avoiding the risk of harmful residues in logos and meeting the safety standards for cosmetic packaging.

Laser engraving uses a high-energy beam of light to directly apply to the surface of a perfume bottle, accurately replicating extremely fine lettering, complex patterns, or brand designs. avoiding problems such as ink smudging and jagged edges common in traditional screen printing.Laser engraving enables precise and differentiated processing, meeting the customized marketing needs of high-end perfume brands.Common perfume bottle materials (glass, crystal, acrylic, ceramic, and metal caps) are all suitable for laser engraving, without requiring different processes for different materials.

Metal labelling is a process of attaching labels or logos made of metal materials (e.g. aluminium, stainless steel, copper, nickel, etc.) to the surface of glass bottles. Metal tags can be custom-cut to fit the shape of glass perfume bottles (round, square, irregular) and fixed to any position on the bottle body through methods such as pasting, riveting, or inlaying, without disrupting the overall design of the bottle. For example, for irregularly shaped perfume bottles, a perforated metal tag can be used to conform to the curves of the bottle,The core value is to enhance the added value of the product and brand image through the texture of the metal material and process innovation.

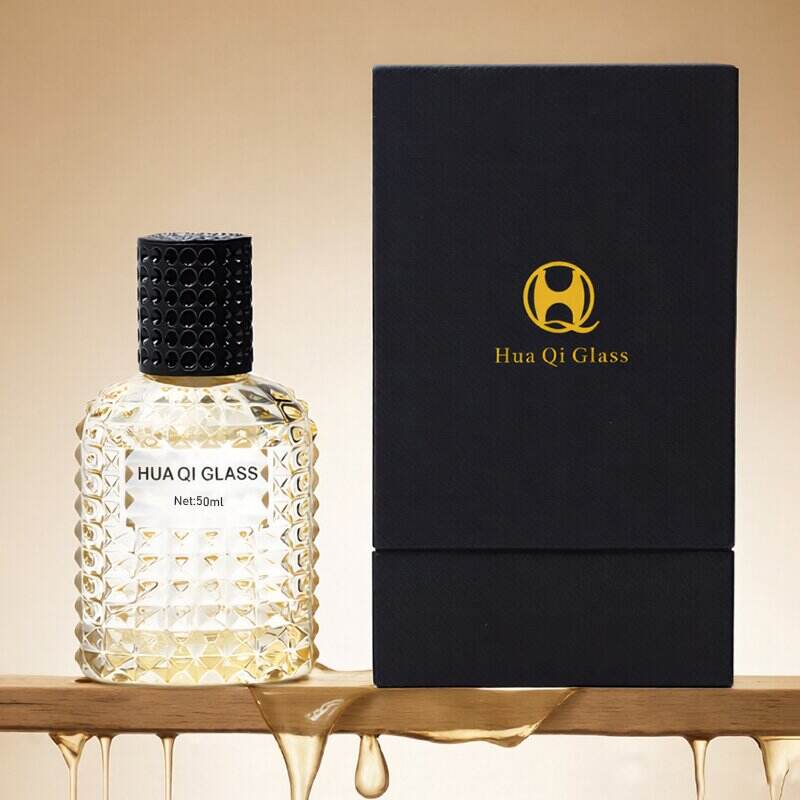

The bottle cap is the "visual focal point" of perfume packaging.We specialize in creating bespoke perfume bottles that capture your brand’s essence. From unique designs to premium finishes, our full customization service transforms your fragrance vision into reality.

Each of our packaging is created with a precise objective: to preserve and enhance the content. The Tailor Made service offers the possibility of having a product with an unprecedented, exclusive design, specially designed for the customer.

HUAQI provides a series of exquisite and luxury perfume packaging. We have more than 5000 bottle models to choose from, and can customize your color and logo,Experience One-stop Luxury Perfume Packaging Solutions

We have professional design team that regularly designs new products to bring your ideas to life.

We have professional production team and QC team are here to ensure quality for you.

We have professional sales team to help you solve your product problems, available 24/7.

One-stop logistics and warehousing enables fast delivery to your doorstep.